Product Overview

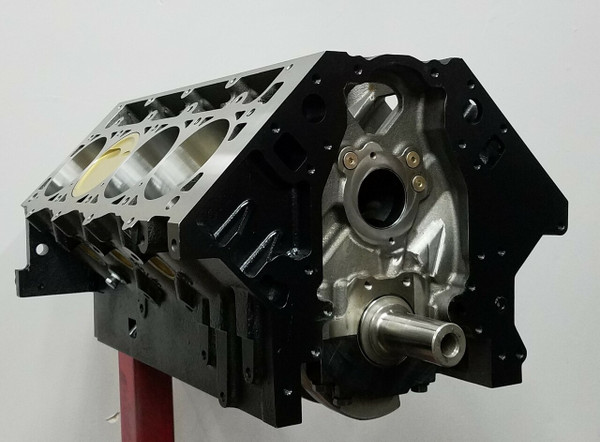

FASTTIMES 408 LS SHORT BLOCKS

- SEASONED 6.0L GEN III OR GEN IV BLOCK

- FORGED 4340 STEEL 4.000" STROKE CRANKSHAFT

- FORGED 4340 STEEL H-BEAM CONNECTING RODS

- FORGED ALUMINUM PISTONS

- STEEL TOP RING SET

- NEW GM MAIN BOLTS

- NEW BLOCK PLUG KIT

- ONE-PIECE CAM BEARINGS

- RACE MAIN AND ROD BEARINGS

FASTTIMES LS PERFORMANCE PRODUCTION SHORT BLOCKS ARE BUILT WITH THE SAME CRAFTSMANSHIP AND QUALITY AS OUR RACE ENGINES. UNLIKE SOME OTHER SHOPS, WE MACHINE, BALANCE, AND ASSEMBLE OUR ENGINES 100% IN-HOUSE. THIS GIVES US 100% CONTROL OVER THE WORK THAT IS PERFORMED TO EACH COMPONENT.

THEY FEATURE A GM SEASONED PRODUCTION BLOCK CORE THAT IS THERMAL CLEANED TO REMOVE ALL PAINT, RUST, SCALE, DIRT, OIL, OR GREASE. EVERY BLOCK GOES THROUGH A DEBURRING PROCESS CHAMFERS CRITICAL EDGES AND HOLES TO PREP FOR MACHINING. THEY ARE THEN ALIGN HONED TO ENSURE THE MAIN HOUSING BORES ARE THE SAME SIZE IN SPEC AND IN LINE. AFTER LINE HONING THE BLOCK IS MACHINED TO ENSURE THE DECK SURFACES ARE PARALLEL TO THE MAINS TO A NOMINAL DECK HEIGHT OF 9.230". NEXT THE BLOCK IS BORED AND THEN FINISH HONED TO 4.030". WE FINISH THESE AT 4.030" DUE TO THE MUCH LARGER SELECTION OF PISTONS THAT ARE AVAILABLE. LIFTER BORES ARE CHECKED FOR SIZE AND HONED TO SIZE AS NEEDED. AFTER FINISH MACHINING THE BLOCK THEN GOES THROUGH A FINAL PREP PROCESS THAT INCLUDES ANY EXTRA CHAMFERING OR DEBURRING THAT MAY BE REQUIRED.

STAGE II SHORT BLOCKS FEATURE A SEASONED GM NODULAR IRON CRANKSHAFT THAT IS CHECKED FOR CRACKS, DEBURRED, AND OIL HOLES ARE CHAMFERED. WHILE WE TRY TO ONLY USE CRANKS THAT HAVE STANDARD-SIZED JOURNALS, SOMETIMES SHORT BLOCKS WILL HAVE CRANKS THAT HAVE BEEN GROUND TO .010"/.010" AT MOST. CRANKSHAFTS ARE SPIN BALANCED ON OUR SUNNEN BALANCER TO WITHIN ONE GRAM ON EACH END THEN MICRO-POLISHED FOR A PERFECT FINISH. EACH CONNECTING ROD IS LOOSENED AND RE-TORQUED THEN CHECKED FOR HOUSING BORE ROUNDNESS, TAPER AND SIZE. ANY RODS THAT DO NOT MEET THE HOUSING BORE SPEC IS MACHINED TO SIZE AND ROUNDNESS. PIN BORES IN THE RODS AND PISTONS ARE HONED TO SIZE FOR PROPER OIL CLEARANCE FOR THE APPLICATION.

ALL COMPONENTS GO THROUGH A MULTI-STEP CLEANING PROCESS TO ENSURE THE BLOCK AND ROTATING ASSEMBLY ARE FREE OF CONTAMINANTS BEFORE ASSEMBLY.

EVERY ENGINE IS ASSEMBLED WITH HIGH QUALITY OIL AND ASSEMBLY LUBRICANTS THAT WE HAVE TRUSTED FOR OVER 30 YEARS.

SEASONED PRODUCTION BLOCKS AND CRANKS MAY HAVE COSMETIC BLEMISHES THAT WILL HAVE ABSOLUTELY NO AFFECT ON DURABILITY OR LONGEVITY. THIS MAY INCLUDE DINGS, DENTS, SCRATCHES OR GOUGES IN NON-CRITICAL LOCATIONS.